The launch of ChatGPT-4.0 has shown us the incredible capabilities of AI, pushing the boundaries of what is possible. This innovation leads us to wonder how AI could be applied to fields like project planning and scheduling, potentially revolutionizing these areas. While there is always concern about technology replacing human jobs, AI in project planning and scheduling can be seen as a powerful tool to enhance human capabilities, reduce errors, and improve efficiency. Here are some ways AI could be integrated into existing project planning and scheduling software:

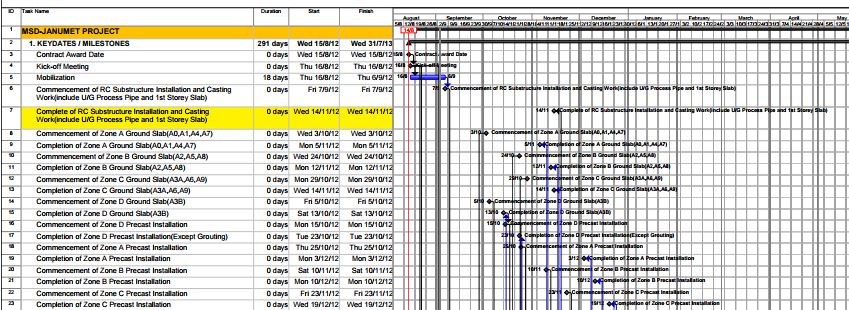

- Milestone Extraction and Schedule Outline: AI could automatically extract scheduling milestones from tender or contract documents, creating an initial high-level project schedule. This schedule would respect the constraints of these milestones and provide a comprehensive view of project phases, helping project managers kickstart the planning process with a solid foundation.

- Project Calendar Selection: By understanding programming specifications, AI can choose the correct project calendar type. This ensures that the schedule aligns with the specific requirements of the project, such as working days, holidays, and other time-related constraints.

- Work Breakdown Structure (WBS) Generation: AI could interpret tender or project specifications to generate a detailed WBS. This structure would outline the project phases, disciplines, systems, and components, providing a clear roadmap for the project execution.

- Typical Work Sequences: AI can offer typical sequences for various types of work, streamlining the planning process. This ensures that project schedules follow industry best practices and efficient workflows, reducing the learning curve for new project managers.

- Drawing Analysis and Quantity Extraction: AI-powered tools could read technical drawings and extract quantities directly from them. This capability would significantly reduce the time and effort required for quantity takeoffs and improve accuracy.

- Interface Listing and Identification: AI can list and identify interfaces in project drawings. This helps in coordinating different project components and disciplines, ensuring that all interfaces are managed effectively and reducing the risk of integration issues.

- Discrepancy Identification: AI could identify discrepancies between drawings and specifications, alerting project managers to potential conflicts early in the planning phase. This proactive approach helps in resolving issues before they impact the project timeline or budget.

- Risk and Critical Path Identification: By analyzing the project plan, AI can identify risks and determine the critical path. This allows project managers to focus on high-risk areas and ensure that key milestones are met, enhancing the overall project control.

- Historical Data Analysis: AI could compile a list of projects with similar scopes, including their corresponding costs and durations. This data-driven approach provides valuable benchmarks and insights for new projects, aiding in more accurate cost and time estimations.

- Specialist Contractor Suggestions: Based on the project requirements, AI can suggest a list of specialist contractors for various works. This helps in finding the right expertise and improving the quality of the project execution.

- Scenario Planning: AI enables scenario planning by evaluating different project strategies and listing the pros and cons of each. This helps project managers make informed decisions and choose the best approach for their project.

- Programme Narrative Generation: AI can generate comprehensive programme narratives that explain the construction strategy, sequences, assumptions, constraints, assumed productivities, and labor histograms. This documentation is crucial for communicating the project plan to stakeholders and ensuring alignment.

- Cashflow Curve Generation: AI could automatically generate cashflow curves, providing a visual representation of the project’s financial plan. This assists in managing project finances and ensuring that funding requirements are met throughout the project lifecycle.

Conclusion

Integrating AI into project planning and scheduling has the potential to significantly enhance the efficiency, accuracy, and effectiveness of project management processes. While there may be concerns about AI taking over jobs, the reality is that AI can empower project managers by automating routine tasks and providing advanced insights, allowing them to focus on strategic decision-making and problem-solving. Embracing AI in project management could lead to more successful project outcomes and a more dynamic and responsive approach to planning and execution.